Toyota Research Institute Begins Using AI for Greener Production Strategies

The institute has teamed up with one of the USA’s leading private research and teaching universities to explore possibilities for greener, sustainable production methods using artificial intelligence.

The move towards sustainable motoring has now reached full throttle thanks to more manufacturers ramping up electric vehicle (EV) production.

Now, there’s even the possibility of using AI to help. Read on for the full story.

For a sustainable future

TRI are implementing artificial intelligence methods to help reduce carbon emissions through the discovery and design of next-generation, sustainable materials.

Teaming up with Northwestern University in Illinois, USA, the collaboration hopes to establish the world’s first nanomaterial “data factory”.

Using AI will be a first step for the industry, as it will with many others – going beyond traditional trial-and-error research with the help of vast data collection.

This will then be given to AI to determine the best material for a specific purpose. TRI and Northwestern believe the new process will be valuable in a range of future projects - from clean hydrogen production to reducing CO2 in the atmosphere.

Brian Storey, TRI Senior Director of Energy and Materials, said:

“Meeting the growing demand for mobility without emitting carbon is a major challenge.

Through this partnership with Northwestern, we have significantly reduced the time it takes to test and find new materials that can be used in batteries and fuel cells to decarbonise transportation.”

Chad Mirkin, Director of the International Institute for Nanotechnology, and the George B. Rathmann Professor of Chemistry at Northwestern, added:

“The ground-breaking research marks an inflection point in how we discover and develop critical materials.

Together with TRI, we’re poised to empower the scientific community to find the best materials that power the clean energy transition.”

How it works

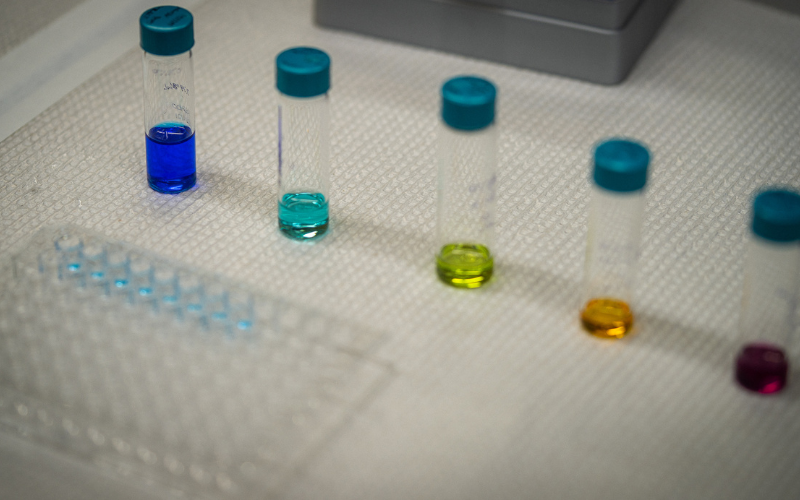

Together, TRI and Northwestern have created a machine-learning algorithm that is capable of synthesising materials.

This is used to sift through Northwestern’s Megalibraries, which are an exhaustive collection of references on new inorganic materials.

These make up the first nanomaterial data factory, which helps mine large sets of high-quality, complex, first-party data.

Before this was created, machine learning algorithms had to use lower-quality data sets that were less consistent.

With this new development, the team hopes that using high-quality data sets to train complex algorithms will allow for more rapid discovery of vital sustainable materials.

Stay up to date with more interesting news and insights on our newsroom.